The High-Luminosity Large Hadron Collider (HL-LHC) project includes the construction of complex underground infrastructures.

Setec TPI, as the representative of the “ORIGIN” engineering joint venture, has steered the studies and construction works for the HL-LHC Point 1 project.

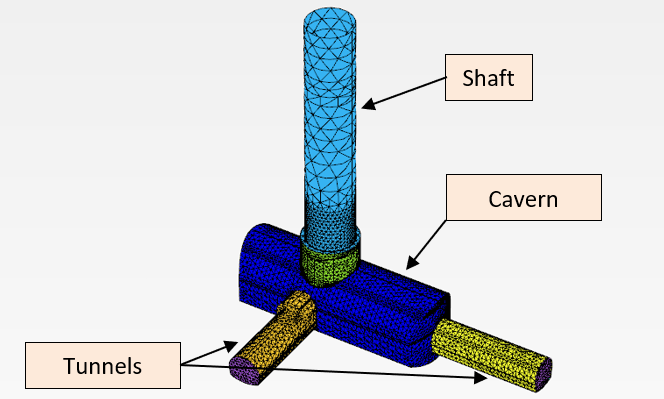

These works consisted of constructing a new shaft, connected to a cavern which is in turn connected to new underground galleries.

At the time of the design and construction studies, Terrasol carried out the design of the US/UW17 cavern, using a three-dimensional finite-element approach (with PLAXIS 3D) in order to take account of the interaction between the underground structures and the high anisotropy of the Red Molasse of the Lower Chattian.

On the basis of the geological field surveys and monitoring measurements during the works phase, it was possible during construction to optimise the support structure for the cavern considered in the design phase.

Using these new construction parameters, Terrasol subsequently carried out numerical back-analysis studies to adjust the soil geotechnical parameters to fit the on-site measurements (in particular convergences and stresses in the shotcrete). These studies confirmed the better quality of the rock mass compared to the expected one and allowed to increase the stiffness of the rock mass and to decrease the stresses on the lining. The latter could thus be optimized in terms of geometry, thickness and reinforcements by means of a 3D calculation with statically indeterminate reactions method carried out by setec als.

Terrasol’s achievements

- Design of the cavern and of the interfaces with the shaft and galleries using complex numerical modelling (2D and 3D)

- Follow-up of the works execution, geological field surveys, monitoring meausrements

- Numerical back-analysis studies to optimize the final lining of the shaft and cavern

Agent Access

Agent Access