The project concerns the construction of a new Air Separation Unit by Air Liquide in the Port of Moerdijk, in the Netherlands.

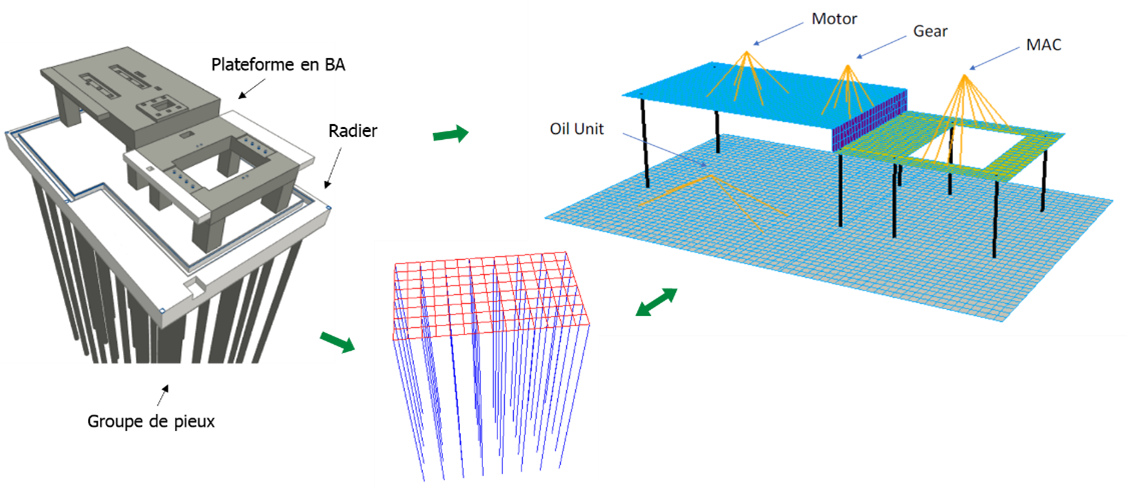

The installation consists of several compressors and motors (units C01, C05 and C50) supported by reinforced concrete structures founded on pile groups.

In order to guarantee the correct normal operation of this equipment, it is necessary to verify that very strict vibration criteria defined by the manufacturers are met.

Terrasol’s mission: verifying the vibratory response of machine supports with respect to the criteria defined by the manufacturers. The conducted study deals with all the steps from the analysis and processing of the raw in-situ test data to the vibratory calculations of the structures.

The dynamic behavior of the soil was characterized by an in-depth comparative analysis of several correlations between the dynamic properties of the encountered soils and the results from in-situ static penetrometer tests (CPT) performed within the framework of the project.

A substructuring analysis approach was used to calculate the vibratory response of the different units. Calculations with a “hybrid” model of the soil and the foundation using SASSI software allowed us to characterize the dynamic response of the foundation (considering the slab-pile-soil and the pile-soil-pile dynamic interaction effects). The calculation of the vibratory response under harmonic loading was performed for each unit using a finite element model (Code_Aster) considering soil-structure interacion (SSI) effects.

The respect of the vibratory criteria in terms of maximum effective velocity (maximum RMS velocity) at the level of the axis of rotation and the support of each machine could finally be verified.

Terrasol’s achievements

- Validation of the vibratory criteria of the project in the design phase

- Justification of a geodynamic model from in-situ static penetrometer tests

- Assistance to the optimization of the support structures

Agent Access

Agent Access