Port Said power plant was erected in 2001. The power plant is using 2 intake pipes in GRP material DN2300 ID to supply water for cooling system and 2 Outfall pipe in GRP ID 2300 for discharging the hot water.

Leakage on the 4 lines have been observed during the last past years. Previous survey indicated that some of GRP pipes are dislocated.

In order to replace some parts of these GRP pipes during plant maintenance phase, earth moving works will be performed and shoring walls will be necessary to secure excavation stability.

In the scope of these works, Terrasol was entrusted with an external control mission by Balineau, the contractor in charge of executing the temporary shoring works consisting of strutted or anchored sheetpile walls.

The first stage consisted of analyzing the available soil data in order to accurately define the soil parameters for shoring wall analysis. Interpreted tests included field testing such as SPT, CPTu and vane shear, as well as lab testing such as identification and triaxial testing (CD, CU+u). The main focus of the analysis is the characterization of the 20 m thick fat clay layer encountered at 10 m depth below the upper silt and sand layers and which controls the stability of the sheetpile wall. The analysis enabled a fine estimation of the clay undrained cohesion cu as a function of the effective vertical stress and its variation with depth.

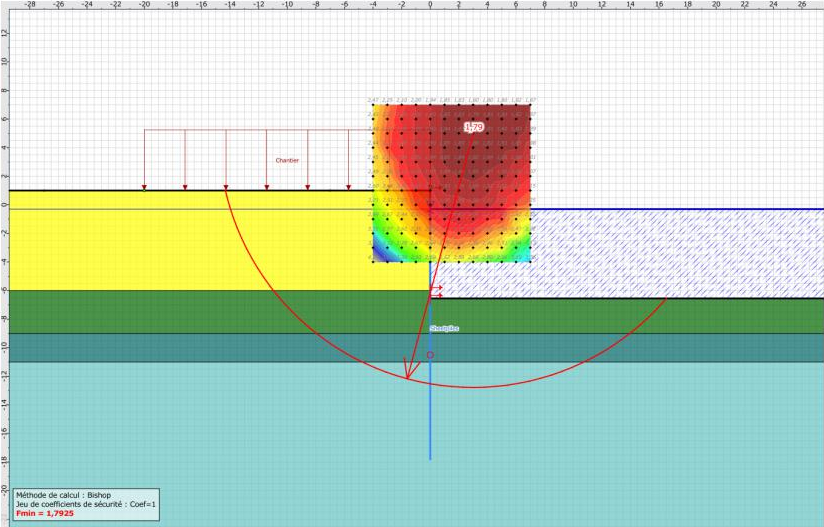

The second stage requested from terrasol was to perform side-checks of the shoring system which required the creation of dedicated models for the different studied sections. The critical aspects of the verifications are the safety on mobilized passive earth pressure which controls embedment depth, the equilibrium of vertical forces in light of negligible bearing resistance of the clay layer and the Kranz stability required to define the distance between the main wall and the reaction wall.

Global stability verifications were also performed using both drained and undrained soil parameters.

The results obtained allowed us to confirm the required section and length for the sheetpiles, determine support reactions for the design of tie rods and struts, and identify critical failure mechanisms.

Terrasol’s achievements

- Geotechnical synthesis

- Verification of the shoring system design

Agent Access

Agent Access