To prepare its response to a call for tenders launched by the Lebanese government, VINCI CONSTRUCTION GRANDS PROJETS contacted SETEC ENERGIE ENVIRONNEMENT (SETEC group) for technical assistance on this operation, with SOGREAH and KHATIB & ALAMI managing the project.

To satisfy the demand as accurately as possible, SETEC ENERGIE ENVIRONNEMENT teamed up with LOMBARDI (to design the dam body and provide the associated geotechnical engineering expertise) and TERRASOL (for the geotechnical design of the ancillary structures, upstream cofferdam, jet-grouting bulkhead, and downstream cofferdam).

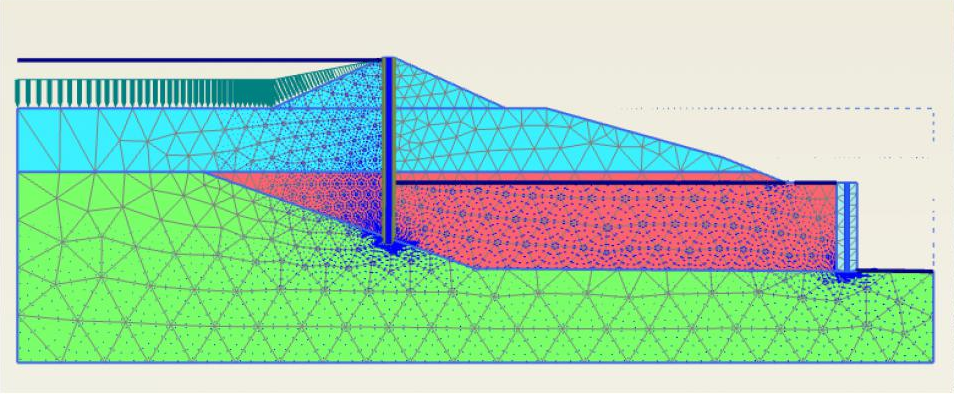

The main structure is a 92-m high RCC (roller-compacted concrete) dam, with 62 m of replacement of alluvial material on the Narh Ibrahim. The upstream and downstream cofferdams consist of a dike with a deep grouted cut-off wall.

The bulkhead consists of an arc-shaped wall executed with the jet-grouting technique and acting as a retaining structure to enable the replacement works for the alluvial material under the base of the dam body.

Terrasol’s assignment consisted of:

- A review of the preliminary design,

- The study of an alternative solution proposed by VINCI CONSTRUCTION GRANDS PROJETS, which consisted of moving the upstream cofferdam (dike) further upstream, building the cut-off wall on the upstream side of the dike (rather than on its axis), and removing the bulkhead.

The result of this study clearly showed the advantages of the alternative solution:

- Solution 1 (without embedment of the cut-off wall in the substratum) does not provide enough safety,

- Solution 2 (with embedment of the cut-off wall in the substratum) presents a risk of overflow due to probable dam settlement, and requires extensive jet-grouting works, the stability of which is uncertain,

- Solution 3 (VINCI’s alternative solution) minimizes the amount of geotechnical works (smaller cut-off wall and no jet-grouting) and reduces the volumes to be pumped.

- This comparative study was carried out using the PLAXFLOW module (PLAXIS software) for flow quantification. In addition, PLAXIS 2D was used to check displacements, as well as stresses and forces on the cut-off wall and the bulkhead.

Terrasol’s achievements

- Review of the preliminary design

- Study of an alternative solution proposed by VINCI CONSTRUCTION GRANDS PROJETS

Agent Access

Agent Access