Materials

1 Concrete

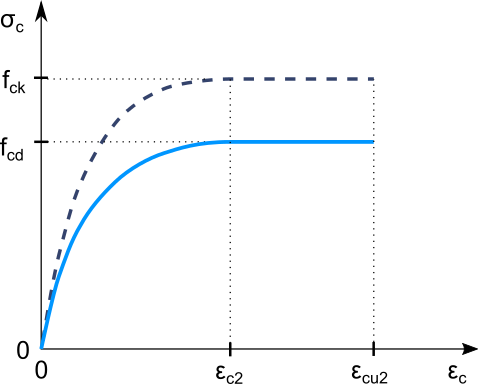

1.1 Constitutive law

The constitutive law of concrete features an elastoplastic behaviour (parabolic-rectangular). \[ \begin{array}{cc}\sigma_c=f_{cd}\left[1-\left(1-\frac{\displaystyle\varepsilon_c}{\displaystyle\varepsilon_{c2}}\right)^n\right]&\;0\leq\varepsilon_c\leq\varepsilon_{c2}\\\sigma_c=f_{cd}&\varepsilon_{c2}\leq\varepsilon_c\leq\varepsilon_{cu2}\end{array} \]

1.2 Allowable stresses and safety factors

1.2.1 French national annex

In this chapter, we provide allowable stresses and safety factors calculation example for a concrete C30/37, according to NF P94-282 §6.4.

Permissible compressive stress of concrete (characteristic value at 28 days): \[ f_{ck}=30MPa \] Maximal value of characteristic compressive strength during processing (Table 6.4.1.1): \[ C_{max}=35MPa \] Empirical coefficients (Table 6.4.1.1): \[ k_1=1.30 \]

\[ k_2=1.05 \]

We consider that integrity checks are not carried out (Table 6.4.1.1), so: \[ k_3=1.00 \] Characteristic compressive strength: \[ f_{ck}^\ast=\frac{min\left(f_{ck},C_{max}\right)}{k_1k_2}=21.98MPa \]

According to NF P94-282 §6.4.2 (7) Note 1, \(f_{ck}^\ast\) should only be used for compressive stress check.

Average compressive strength: \[ f_{cm}=f_{ck}+8MPa\;=38MPa \] Average tensile strength: \[ f_{ctm}=0.3f_{ck}^{2/3}\;=2.90MPa \] Characteristic tensile strength (5%): \[ f_{ct;k;0.05}=0.7f_{ctm}\;=2.03MPa \] Allowable SLS stresses (NF P94-282 §6.4.1 (8)):

- Mean stress:

\[ \sigma_{c,mean}=0.3k_3f_{ck}^\ast=6.6MPa \]

- Maximal stress:

\[ \sigma_{c,max}=0.6\cdot min\left(k_3f_{ck}^\ast;f_{ck}\right)=13.2MPa \]

Allowable ULS resistances (Eurocode 2 §3.1.6) :

\(\alpha_{cc}=1.0\), \(\alpha_{ct}=1.0\), \(\gamma_c=1.5\)

- Compressive:

\[ f_{cd}=\alpha_{cc}\frac{min\left(k_3f_{ck}^\ast;C_{max}\right)}{\gamma_c}=14.7MPa \]

- Tensile:

\[ f_{ctd}=\alpha_{ct}\frac{f_{ctk,0.05}}{\gamma_c}=1.35MPa \]

Allowable Accidental ULS resistances (Eurocode 2 §3.1.6) :

\(\alpha_{cc}=1.0\), \(\alpha_{ct}=1.0\), \(\gamma_c=1.2\)

- Compressive:

\[ f_{cd}=\alpha_{cc}\frac{min\left(k_3f_{ck}^\ast;C_{max}\right)}{\gamma_c}=18.3MPa \]

- Tensile:

\[ f_{ctd}=\alpha_{ct}\frac{f_{ctk,0.05}}{\gamma_c}=1.7MPa \]

1.2.1.1 Belgian national annex

In this chapter, we provide allowable stresses and safety factors calculation example for a concrete C30/37, according to Belgian national annex (BNA).

Permissible compressive stress of concrete (characteristic value at 28 days): \[ f_{ck}=30MPa \] Maximal value of characteristic compressive strength during processing (Table 6.4.1.1): \[ C_{max}=35MPa \] Empirical coefficient (BNA §2.4.2.5 (2)): \[ k_f=1.1 \] We consider that integrity checks are not carried out, so: \[ k_3=1.0 \] Characteristic compressive strength: \[ f_{ck}^\ast=\frac{min\left(f_{ck},C_{max}\right)}{k_f}=27.27MPa \] Average compressive strength: \[ f_{cm}=f_{ck}+8MPa\;=38MPa \] Average tensile strength: \[ f_{ctm}=0.3f_{ck}^{2/3}\;=2.90MPa \] Characteristic tensile strength (5%): \[ f_{ct;k;0.05}=0.7f_{ctm}\;=2.03MPa \] Allowable SLS stresses:

- Mean stress:

\[ \sigma_{c,mean}=0.3k_3f_{ck}^\ast=8.2MPa \]

- Maximal stress:

\[ \sigma_{c,max}=0.6\cdot min\left(k_3f_{ck}^\ast;f_{ck}\right)=16.4MPa \]

Allowable ULS resistances (Eurocode 2 §3.1.6) :

\(\alpha_{cc}=0.85\), \(\alpha_{ct}=1.0\), \(\gamma_c=1.5\)

- Compressive:

\[ f_{cd}=\alpha_{cc}\frac{min\left(k_3f_{ck}^\ast;C_{max}\right)}{\gamma_c}=15.5MPa \]

- Tensile:

\[ f_{ctd}=\alpha_{ct}\frac{f_{ctk,0.05}}{\gamma_c}=1.35MPa \]

Allowable Accidental ULS resistances (Eurocode 2 §3.1.6) :

\(\alpha_{cc}=0.85\), \(\alpha_{ct}=1.0\), \(\gamma_c=1.2\)

- Compressive

\[ f_{cd}=\alpha_{cc}\frac{min\left(k_3f_{ck}^\ast;C_{max}\right)}{\gamma_c}=19.3MPa \]

- Tensile

\[ f_{ctd}=\alpha_{ct}\frac{f_{ctk,0.05}}{\gamma_c}=1.7MPa \]

2 Steel

2.1 Constitutive

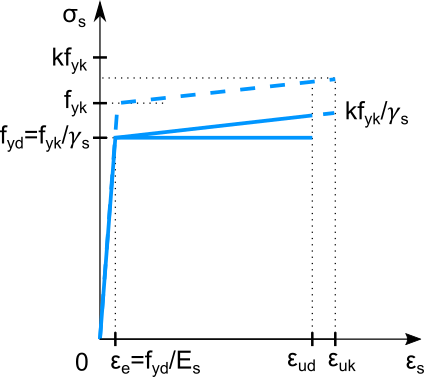

The constitutive law of steel features an elastoplastic behaviour.

According to EN 10080, Eurocode 2 defines three ductility classes :

- Class A: normal ductility (welded mesh made of drawn or cold worked wire)

\[ \sigma_s=432.71+952.38\varepsilon_S≯454MPa \]

- Class B: high ductility (hot-rolled HA bars)

\[ σ_s=433.20+727.27ε_S≯466MPa \]

- Class C: very high ductility (special purpose steels; seismic constructions)

\[ σ_s=432.84+895.52ε_S≯493MPa \]

National annex provide ratio between ultimate and characteristic steel strain:

| National annex | \(\varepsilon_{ud} / \varepsilon_{uk}\) |

|---|---|

| French | 0.9 |

| Belgian | 0.8 |

For instance, according to the French National Annex:

| Ductility | \(\varepsilon_{ud}\) | \(\varepsilon_{uk}\) |

|---|---|---|

| A | 22.5 ‰ | 25 ‰ |

| B | 45 ‰ | 50 ‰ |

| C | 67.5 ‰ | 75 ‰ |

The ultimate strain of the elastic zone (\(\varepsilon_e\)) depends in any case on the considered combination. In the case of an ULS combination (persistent or transient): \[ f_{yd}=\frac{f_{yk}}{\gamma_s}=\frac{500MPa}{1.15}=435MPa \]

\[ E_s=200000MPa \]

\[ \varepsilon_e=\frac{f_{yd}}{E_s}=\frac{435MPa}{200000MPa}=2.175‰ \]

3 Notes

3.1 Stresses

| Symbol | Unit | Description |

|---|---|---|

| \(f_{ck}\) | MPa | Permissible compressive stress of concrete (characteristic value at 28 days) |

| \(C_{max}\) | MPa | Characteristic compressive strength during processing |

| \(k_1\) | - | Empirical coefficient, depends on the method of concrete pouring in the ground |

| \(k_2\) | - | Empirical coefficient, depends on the concrete casting difficulties related to the geometry of the structure |

| \(k_3\) | - | Empirical coefficient, depends on whether integrity checks are carried out |

| \(f_{ck}^*\) | MPa | Characteristic compressive strength considered in the calculation of concrete walls |

| \(f_{cm}\) | MPa | Average compressive strength |

| \(f_{ctm}\) | MPa | Average tensile strength |

| \(f_{ct;k;0.05}\) | MPa | Characteristic tensile strength (5%) |

| \(f_{cd}\) | MPa | Permissible compressive stress of concrete (design value) |

| \(\alpha_{cc}\) | - | Coefficient taking into account the long-term effects on the compressive strength of concrete > French national annex = 1.0 > Belgian national annex = 0.85 |

| \(\alpha_{ct}\) | - | Coefficient taking into account the long-term effects on the tensile strength of concrete > French national annex = 1.0 > Belgian national annex = 1.0 |

| \(f_{yd}\) | MPa | Permissible stress of steel (design value) |

| \(f_{yk}\) | MPa | Permissible stress of steel (characteristic value) |

| \(\gamma_c\) | - | Partial coefficient on concrete strength |